MC1056 - Kapsül Tip Slip Rings

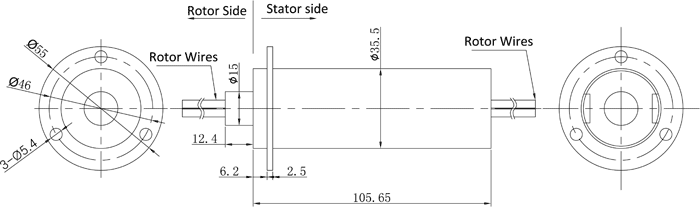

Dış Çap 35.50mm(0.97"), uzunluk 105.6mm, 76 kablo * 2A (sinyal)

MC1056 slip ringler küçük ve kompakt yapıda 35.50mm(0.97") dış çaplı, 105.6mm uzunlukta, kapsül tipli, standart, satışa hazır slip ringler olup, basitleştirilmiş elektrik bağlantıları için renk kodlu ana kablolar statorda ve rotorda kullanılır. Her bir iletken için 90° V-kanal iletken tasarımı kullanılır.

MC10569, MC1056'un üst versiyonudur, daha yüksek performanslı daha uzun ömürlüdür, daha yüksek devir hızına sahiptir, daha az gürültü çıkartır.

| PART # |

OD * L |

SIGNAL/2A |

4A |

8A |

15A |

TOTAL WIRES |

DOWNLOAD |

| MC1056 |

35.5mm*105.6mm |

76 |

0 |

0 |

0 |

76 |

PDFCAD |

| Shared Specifications |

| Wires |

76(see table as above) |

Current |

Signal(2A) |

| Voltage |

240 VDC/VAC |

Max speed |

100RPM |

| Contact Material |

Precious Metal:gold-gold |

Contact Resistance |

<150mOhm(AWG28#,250mm) |

| Housing Material |

Plastics |

Torque |

0.15N.m |

| Working life |

depends on working speed |

Electrical noise |

<10mΩ |

| Dielectric strength |

600VDC@50Hz |

Lead Wire |

UL Teflon® Awg28 |

| Insulation resistance |

1000MΩ@500VDC |

Lead Lengths |

250mm |

| Operating Temp. |

-40°C to 80°C |

Protection |

IP51 |

| Mechanical vibratio |

MIL-SID-810E |

Humidity |

10% to 90% RH |

| Materials |

Lead Free,RoHS compliant |

CE Certified |

YES |

|

Notes:

1)The operational life of the unit is dependent upon rotational speed, environment and temperature.

2)Lead Wire size: 2A/signal -> AWG28, 4A -> AWG22, 8A -> Awg16, 15A -> Awg14, colored code.

3)Electrical noise is dependent upon the rotating speed and current,voltage.

TABLE 2:

| |

Max Speed |

Working life |

Torque |

Housing

Material |

Electrical noise①

@10Rpm |

| MC1056 |

100RPM |

depends on working speed |

0.15 N·m |

Plastics |

10mΩ |

| MC10569 |

300RPM |

1depends on working speed |

0.05 N·m |

Metal |

4mΩ

|

|

Standard drawings:

24 wires for one group color. from 25 ... 48, repeat the same color as 1 ... 24

| Lead wire Color codes |

| Rings# |

Color Code |

Rings# |

Color Code |

Rings# |

Color Code |

Rings# |

Color Code |

| 1 |

BLK |

7 |

BLU |

13 |

WHT BLK |

19 |

WHT BLU |

| 2 |

BRN |

8 |

PURPLE |

14 |

WHT BRN |

20 |

WHT PURPLE |

| 3 |

RED |

9 |

GRY |

15 |

WHT RED |

21 |

WHT GRY |

| 4 |

ORN |

10 |

WHT |

16 |

WHT ORG |

22 |

CRY STAL |

| 5 |

YEL |

11 |

PINK |

17 |

WHT YEL |

23 |

BLK RED |

| 6 |

GRN |

12 |

AZURY |

18 |

WHT GRN |

24 |

WHT BRN

|

- If you don't see what you want in this website,let us know; we may already have it designed or we will modify a design to meet your requirements. In many cases the specifications in the catalog can be changed to include bore size, circuits number, higher current/voltage,flange, lead wire length,shielding,connectors,higher speed,IP68,military grade,higher temperature, mixed with pneumatic/hydraulic capability. Please ask if you don't see exactly what you need as only a small fraction of our Moflon slip rings are included in this catalog!

-

- MC10569 is the high-end version corresponding to MC1056.

- Optional flange mounting.

- Specified connectors and Heat-shrink tube.

- Longer lead lengths available.

- High temperature is optional.

- Military Grade.

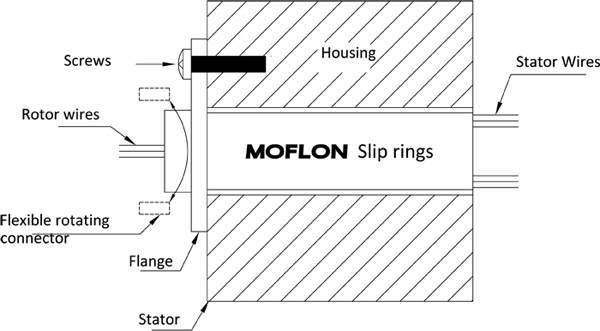

Flange Mounting Instructions

1. Align the mounting holes in the flange to mounting base and install flat washers and thread forming screws (NOT SUPPLIED) for plastic. Securely tighten screws.

2. Route the wiring and make the necessary connections. Do not allow the wiring to restrict free rotation of the slip ring.

3. Position a screw or dowel (NOT SUPPLIED) in the anti-rotation tab to the dimension as shown.

CAUTION: Because of possible geometric mismatching between the customer��s application and the slip ring, 'hard mounting' of both ends of the slip ring (i.e., securing the rotor and stator such that there is NO floating during operation) is not recommended and may cause premature failure

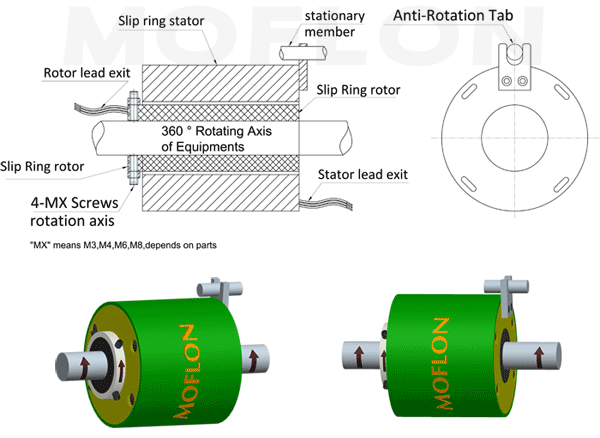

Shaft Mounting Instructions(For Through bore style)

1.Main shaft mouted units:

A.Position the slip ring in the desired location and tighten both set screws to the shaft.Maximum torque 25Ib-in(DO NOT OVER TORQUE)

B.Route the wiring and make the neccessary connections.Do not allow the wiring to restrict free rotation of the slip ring.Do not constrain wiring such that wire flexing occurs.Doing so will ultimately cause failure(breakage of the wiring).

2.Housing mouted units:

A.Anti-Rotation tap used for connecting the stator of slip ring with the stationary member of euipment

B.Route the wiring and make the neccessary connections.Do not allow the wiring to restrict free rotation of the slip ring.

Typical Application

- CCTV Monitoring System.

- Electrical test equipment.

- Medical equipment.

- Rotary table

- Robotics

- Laboratory equipmen

- Manufacturing and process control equipment